Contact Us

TEL+86-411-62775690

FAX+86-411-62775691

MOBILE+86-13842676180

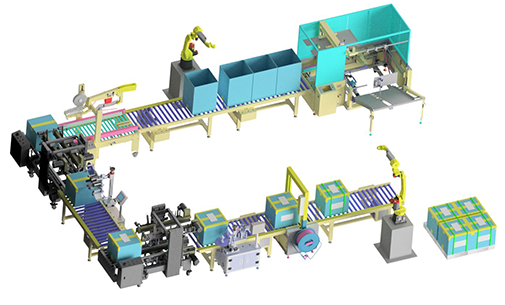

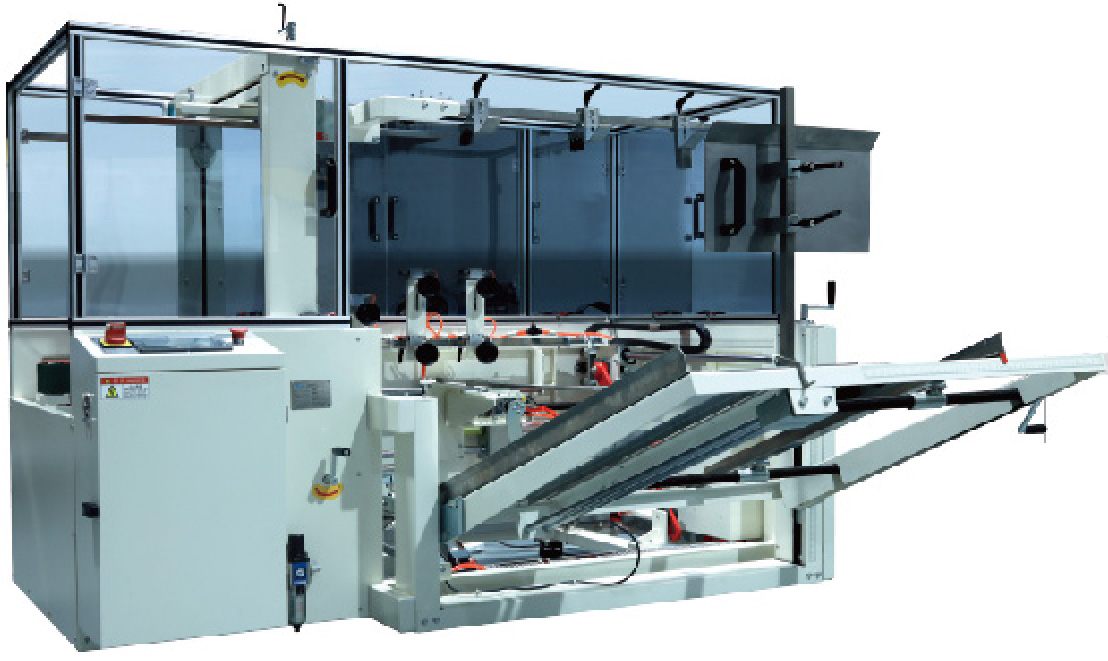

Automatic packaging production line Realization of low-cost, labor-saving IOT production

The box making machine is PLC + touch panel control, which makes operation easier and reduces packaging costs. It is an indispensable facility for automated lines.

Box making machine-specialty

1.Ideal for continuous box making with the same case size.

2.Side-belt transport system that reduces the burden on the case.

3.Adjusting the width of the side belt and the height of the taping head (up and down) is easy with the handle.

4.There is also a loading table and unloading roller that are easy to work with (optional)

5.Equipped with large casters for easy movement in the workplace.

| Specifications | |

| Model | CK-L |

| Machine dimensions | Total width 2150mm |

| Total length 2050 mm | |

| Total height 1650 mm | |

| Weight | about 700 kg |

| Case size | Width 250-550 mm |

| Height 130-450mm | |

| Length 150-450mm | |

| Tape width | 38〜50mm |

| Outlet height | 640mm |

| Processing | capacity 6-10 cases/min |

| Maximum power supply capacity | Three-phase 110V/220V/380V 0.5Mpa 0.3kw |

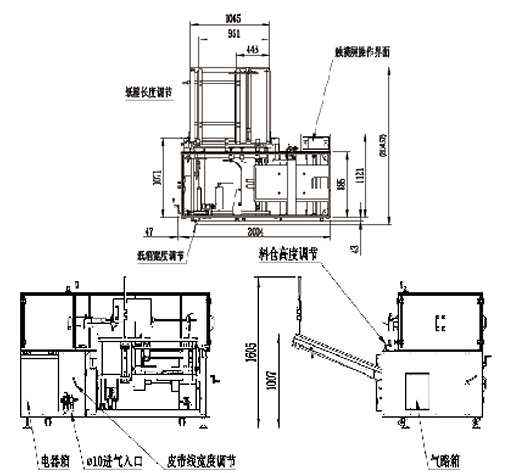

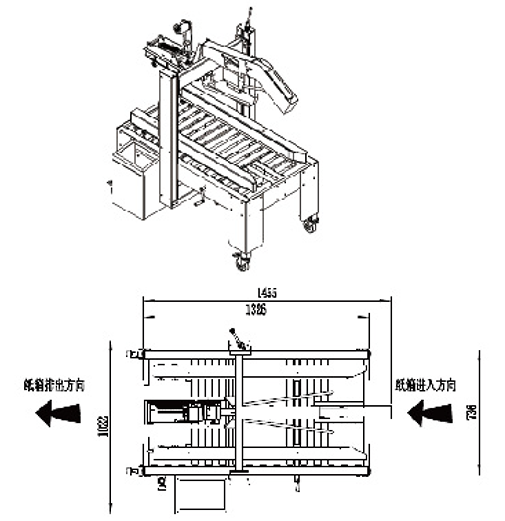

The sealing machine closes the lip of the carton automatically after putting the goods in the cartons,seals the cartons with tape at the same time.

I type sealing machine-specialty

1.Ideal for continuous box sealing with the same case size.

2.Side-belt transport system that reduces the burden on the case.

3.Adjusting the width of the side belt and the height of the taping head (up and down) is easy with the handle.

4.There is also a loading table and unloading roller that are easy to work with (optional).

5.Equipped with large casters for easy movement in the workplace.

| Specifications | |

| Model | CF-L |

| Machine size | Total width 1050mm |

| Total length 1500 mm | |

| Total height 1500 mm | |

| Weight | about 250kg |

| Case size | Width 150-450 mm |

| Height 130-450mm | |

| Length 250-550mm | |

| Tape width | 38〜50mm |

| Outlet height | 640mm |

| Processing capacity | 10-14 cases/min |

| Maximum power supply capacity | Three-phase 110V/220V/380V 0.5Mpa 0.3kw |

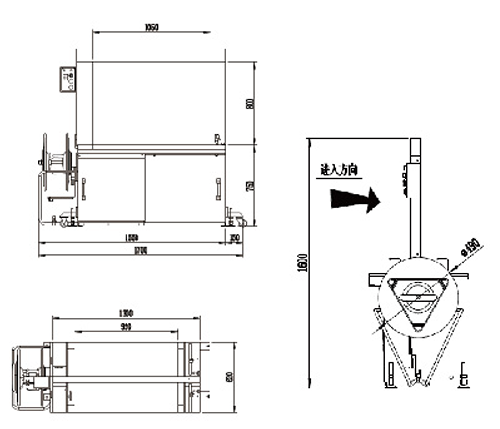

Can automatically complete the bundling process of tape gathering, heat sealing, cutting, and out of the tape.

Strapping machine-specialty

1.Mitsubishi PLC control, full function and easy operation.

2.The flip-up type makes maintenance easy.

3.Suitable for PP or PET tape.

4.Adhesive tape time adjustable.

5.Power saving with fully automatic line built-in and automatic standby.

| Specifications | |

| Model | CD-H1 |

| External dimensions | Total width 1700 mm |

| Total length 620 mm | |

| Total height 1600 mm | |

| Weight | about 350kg |

| Band line width | 9mm,12mm,15.5mm |

| Tightening capacity | 75㎏ |

| Packing speed | 2.2 S/piece |

| MAX packing size | 1050*800mm |

| MIN packing size | 100*50mm |

| Power supply specifications | Three-phase 220V/360V 0.5Mpa 0.3kw |